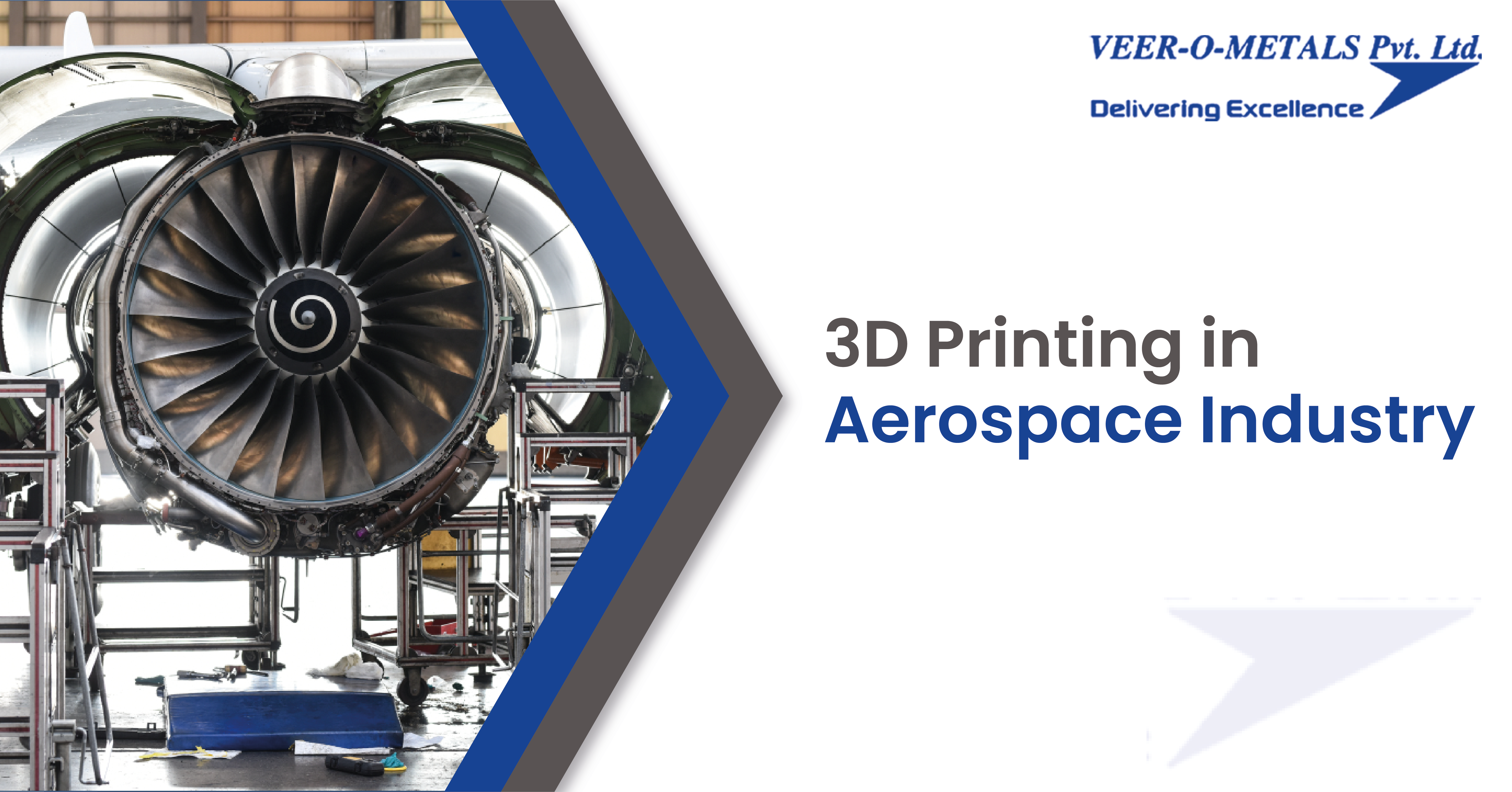

6 MOST POPULAR INDUSTRIES TO USE METAL 3D PRINTING

Will you disagree with me if I say that the long-term success of any society is highly dependent on its manufacturing? I hope you will not. Every society needs a very strong and vibrant manufacturing base. There is a well-known saying that 'If you always do what you always did, you'll always get what you have always got. This clearly states the significance of development and automation in the manufacturing industry. Additive manufacturing is fundamentally changing what we can do. There are three key elements to effectively utilize the additive manufacturing process. Additive thinking, accessible processes and cost are those elements which provide the most efficient solutions to the hindrances in the additive manufacturing sector. Metal additive manufacturing is the one that requires special mention here. Let us understand the concept, types, and major metal additive manufacturing applications.

METAL 3D PRINTING: EVERYTHING YOU NEED TO KNOW

The beauty of art lies not only in what all elements we add to it but also in, what elements we take out from it. This is what vests under the concept of Metal Additive Manufacturing, in common terms, referred to as Metal 3D Printing. It is an output of the biggest leap in technology that produces three-dimensional parts layer by layer from a metal material. In the modern era of technological innovations, there is no point in asking if it is possible to 3D print items from metal. The technology of Metal Additive Manufacturing makes it possible in the best way. Let us know how metal additive manufacturing works, the different types of metal 3D printing, its likely advantages and possible applications.

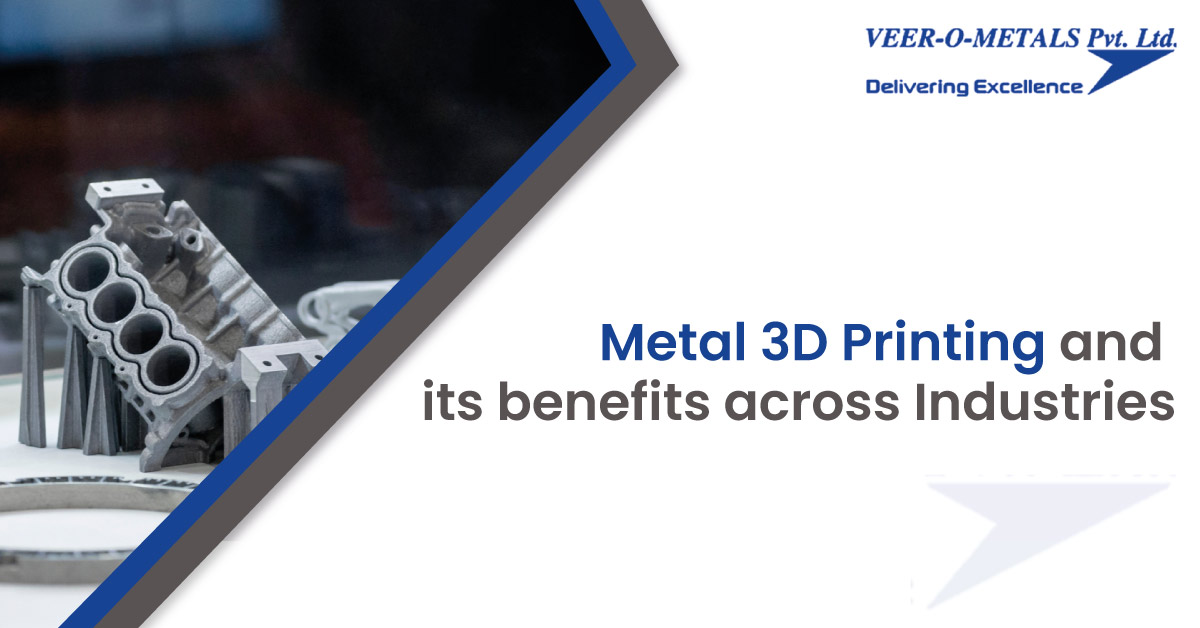

METAL 3D PRINTING & ITS BENEFITS ACROSS INDUSTRIES

3D Printing is a technology where design files (CAD Models) of the Metal Part to be manufactured is sent to the 3D printer, which prints functional 3D models layer by layer from the metal material. Thus 3D printing is used to manufacturing objects (Parts, Prototypes, tools & even assemblies) directly from their CAD models without any cutter, tools and jigs & fixtures.

METAL 3D PRINTING & ITS IMPACT ON THE ENVIRONMENT

This technology makes it possible for manufacturers to produce complex metal parts without any design constraints of traditional manufacturing. There are numerous benefits of 3D printing over Traditional Manufacturing as it results in elimination of Tooling and Fixture Costs and complex parts can be corrected and printed quickly.